Projects >POLEA Lab > Lab Robotics / Exoskeletons

This Lab is focused on demonstration, testing, validation and scaling of robotic solutions and industrial exoskeletons for:

- Operator support

- efficient industrial automation

- intra-logistics

- Industry 5.0

What is it?

It is a specialized space for technological demonstration, training, feasibility tests, and industrial scaling of solutions. We show elements that reduce operation time, make work easier for operators, avoid risks, and reduce costs.

We have exoskeletons, collaborative, mobile and autonomous robots. Mobile robotics, given its need for space, is shown through an additional large showroom.

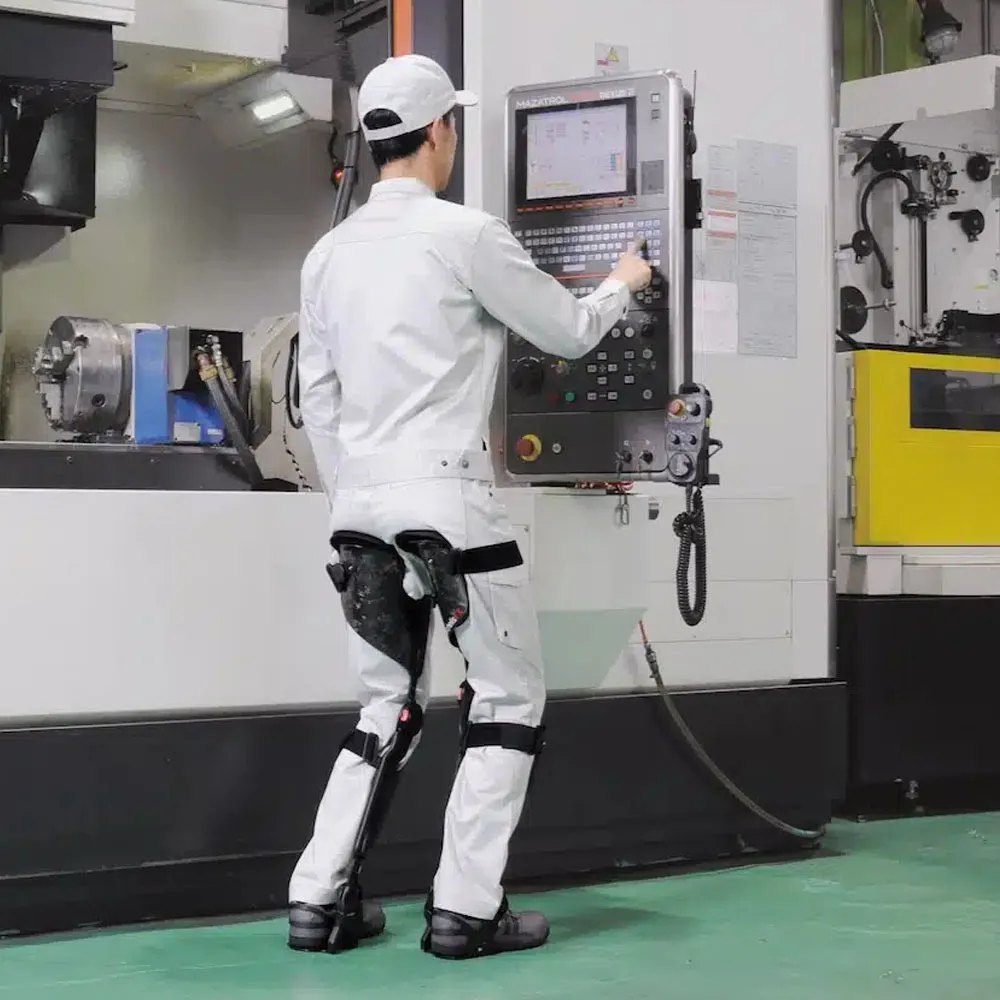

Industrial exoskeletons

Apex 2 Exosuit

Repetitive movement of loads

Affected body area: Back and lumbar region

A passive exoskeleton designed to correct posture and assist workers in lifting and handling tasks. It is adjustable to different physiognomies with different resistances. Allows total mobility.

Available in the lab

Exosoft

Repetitive movement of loads

Affected body area: Back and lumbar region

Ergonomic textile exoskeleton for lumbar support. The action of the muscles is replaced by “artificial muscles” formed by elastomers of variable deformation that support the person in the realization of any movement in which the lumbar area is involved. It allows full mobility of the body.

Available in the lab

IX Shoulder Air o Ottobock Shoulder

Tasks in elevation and/or extension

Body area affected: Shoulders and deltoids

Passive industrial exoskeleton designed to reduce the physical load on workers who perform tasks above shoulder level or in extension, such as assembly lines, maintenance or construction. It has a system of tensioners, with which you can regulate the assistance provided in each of the arms independently.

Available in the lab

Exoshoulder

Tasks in elevation and/or extension

Area of the body affected: Shoulders, arms and deltoids

Portable exoskeleton that provides support to the operator’s arms, helping him/her to maintain proper postures and lighten loads when performing repetitive tasks with the upper extremities in elevated positions. Differtent sizes.

Available in the lab

FX Stick

Semi-sitting works

Area of the body affected: Legs, knees and back.

A passive exoskeleton that allows the user to adopt a semi-sitting posture while standing, relieving leg and back fatigue during prolonged work.

Available on request.

Back up Tool

Kneeling works

Affected body area: Legs, back and knees

Passive exoskeleton designed to relieve back and knees in bending applications. Thanks to its various add-ons, it is a perfect tool for most work on the ground.

Available on request

CX Soft Wrist

Weight handling

Body area affected: Wrists

Passive exoskeleton designed to support the wrist joint in repetitive or weight-bearing tasks. Can include up to 3 metal splints, to provide structural support that stabilizes the wrist, limiting excessive flexion and reducing muscle strain.

Available on request

CX Easy Neck

Overhead tasks

Affected body area: Neck and cervical region

Passive exoskeleton to relieve neck strain during overhead work. Thanks to its light weight and adjustability, it prevents neck injuries.

Available in the lab

CX Power Thumb

Fingertip insertion or tapping tasks

Affected body area: Hands and fingers

Exoskeleton to protect the thumb in insertion or pulsation tasks. This exoskeleton prevents finger and hand injuries. Available in different sizes for a good fit.

Available in the lab

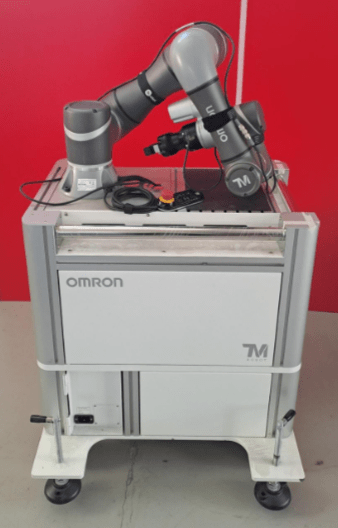

Collaborative Robotics

OMRON TM5-700 Collaborative Robot

Collaborative industrial robot designed to automate repetitive tasks such as monitoring, loading and unloading parts, assembly, bolting or light handling. With a maximum reach of 700 mm and a payload capacity of up to 6 kg, the TM5-700 combines precision, flexibility and ease of programming. Thanks to its integrated vision systems and safe design, it can work alongside operators without the need for physical barriers, making it an ideal solution for production environments looking to improve efficiency and reduce operating costs.

Available in the lab

Universal Robots Collaborative Robot UR5e

Versatile collaborative industrial robot designed for tasks such as machine tending, palletizing and packaging. It has a payload of 5 kg and a reach of 850 mm, offering precision and flexibility for easy integration into different production processes. Its intuitive programming and integrated safety enable safe collaboration with operators, optimizing automation in diverse industrial environments.

Available in the lab

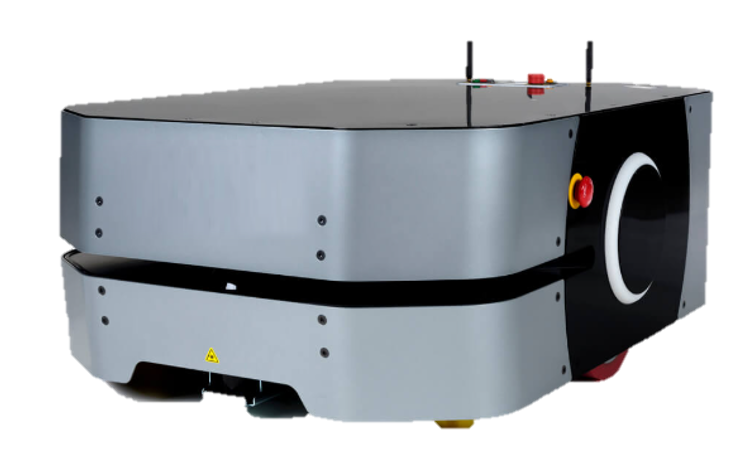

Mobile Robotics

KUKA KMP 600 Mobile Robot

AMR platform for load transport by means of differential traction and elevation system. Capable of transporting loads of up to 600 kg in medium size, complying with the most demanding industrial safety standards. Thanks to its autonomous navigation based on maps and integrated sensors, the KMP 600 can operate safely in environments shared with people, optimizing internal logistics flows. It offers high positioning accuracy, connectivity with MES/ERP systems and flexibility to adapt to different types of cargo and processes. They come with integration software with other possible systems in a regular work scenario, and that in the demonstrations of these elements can be seen not only its operation, but also the possibilities of integration.

Disponible en showroom adicional robótica móvil

Mobile Robot OMRON LD-250

Autonomously navigating mobile robot designed to move material dynamically and safely in complex industrial environments. Capable of carrying loads up to 250 kg, it adapts to changing spaces without requiring infrastructure modifications. It uses mapping technologies and integrated sensors to avoid obstacles and optimize routes in real time.

Available in the lab

APTIX PRAMAC autonomous stacker-robot

Robot with autonomous movement designed to transport and stack goods with precision and efficiency. Equipped with intelligent navigation systems, it is able to operate safely in mixed environments, where traditional operations coexist with automated solutions. Its ability to easily integrate into existing logistics flows makes it a key tool for improving productivity, reducing errors and optimizing load handling in warehouses and distribution centers.

Available on request

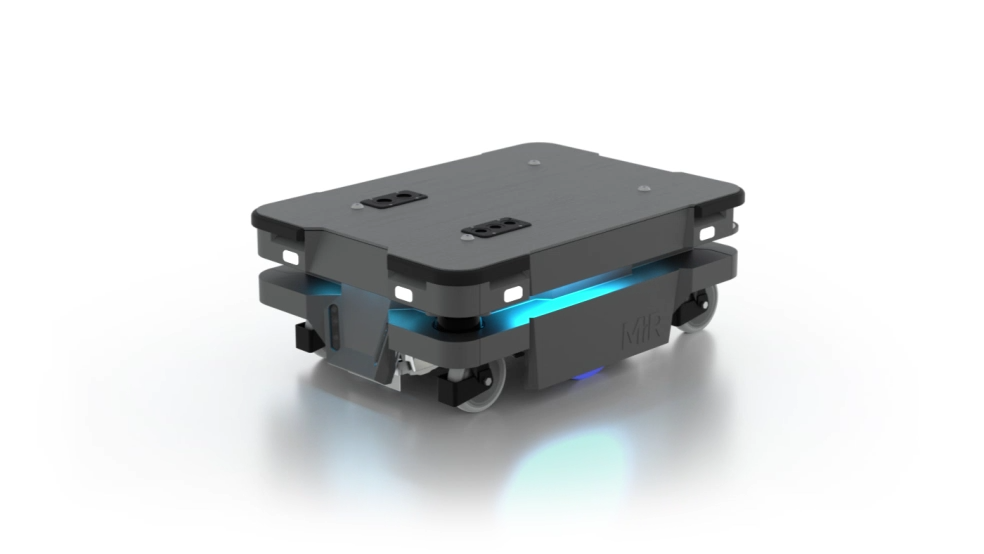

AMR platform, MiR 250

Autonomous mobile robot with compact dimensions (580 x 800 mm and 30 cm high), designed for efficient transport of loads up to 250 kg. With a speed of up to 2 m/s and the ability to move through narrow aisles of only 80 cm, it is ideal for dynamic and demanding industrial environments. Its robust design allows 24-hour continuous operation, thanks to the quick battery replacement option. It offers safe navigation using advanced sensors, and can be easily integrated into automated logistic flows. They also include integration software with other possible systems in a regular work scenario, and in the demonstrations of these elements you can see not only its operation, but also the possibilities of integration.

Available in showroom.

Robotic quadruped V1. 33

Autonomous four-legged robot designed to move with agility in different environments, both indoors and outdoors. It has compact dimensions of 70 x 40 x 50 cm and weighs approximately 18 kg. It can reach speeds of up to 1.8 meters per second and carry loads of up to 5 kg. Its autonomy is up to 2 hours, with interchangeable battery for prolonged use. It has integrated sensors and stereo cameras. It can be controlled autonomously or by teleoperation via Wi-Fi or 5G connection.

Available in the lab

Assisance or service robotics

uLog LIFT 150

Autonomous mobile robot designed to transport and lift loads up to 150 kg in industrial or logistic environments. It has dimensions of 74 x 50 x 124 cm and weighs approximately 78 kg. It can move at a maximum speed of 1.2 m/s and operate with great precision. Its autonomy reaches 10 hours, with a charging time of about 5.5 hours. It is capable of passing through spaces of at least 80 cm wide. It communicates via Wi-Fi, Bluetooth and 4G/5G networks, and offers different navigation modes (free, lane, tracking or mixed).

Available in the lab

Lab Services

The services provided by the Lab are free of charge for SMEs in Castilla y León, with the exception of the complete development of prototypes. If you are not an SME, or you are not located in Castilla y León, you can also request the services, and we will try to help you by means of a previous technical-economic proposal, and search, if necessary, for alternative lines of aid.

Our prices, in case of services that are not free of charge, are adjusted to actual costs, without any commercial margin.

Technological demostration

We carry out basic demonstration sessions in the lab and customized demonstrations according to the customer’s needs.

Testing in a real working scenario

We travel to the customer’s facilities so that they can test the equipment in their real work scenario, in order to receive feedback and be able to adjust or develop future adaptations. The loan of the equipment is always temporary, normally limited to a maximum of 7 days.

Feasibility analysis for equipment adaptation or customization

If the client indicates the need to adapt the equipment, we carry out a feasibility analysis, through the compilation of technical and functional specifications, and cost assessment.

Development of adaptations or proofs of concept of new solutions

If the feasibility analysis is positive, we develop the necessary adaptations to the equipment, so that it can be adjusted to the customer’s needs. In the case of not being able to cover the specifications through an adaptation, we develop proofs of concept of new equipment.

DIHBU can develop prototypes through the Lab, but always in collaboration with the final customer, and counting on R&D areas of collaborators, usually its own technological members.

Prototypes are not eligible for a free service under the POLEA LAB project, but we can refer the customer to other funding programs that can partially or totally cover these costs.

Validation of new solutions

The Lab can validate prototypes developed by third parties. In this sense, any SME in Castilla y León can request a validation of a prototype of robotic equipment for a specific use or application. The Lab can locate the most appropriate validation scenario within the industry of Castilla y León.

Support for industrial scale-up

Star service of the Lab, oriented to support manufacturing processes of first units and short series after the validation of a prototype. The objective is to ensure that future manufacturing of new equipment is carried out in Castilla y León, either by the client itself or through manufacturing agreements with consolidated companies.

Technical training

From the lab we can offer specialized technical training on any robotic element or exoskeleton, within the scope of the project. This service is very useful to train workers before the implementation of new equipment.

Where are we?

Lab: ITCL General Services Building, street level, C/López Bravo, 70, Polígono Industrial Villalonquéjar, Burgos, Spain.

Additional Mobile Robotics Showroom: Keyland Building. Polígono Industrial Monte de la Abadesa, Burgos, Spain

Are you interested in visiting us or requesting an advanced service?

Contact us

Technical director: Borja Álvarez

Mobile: +34 628251242